Irregular parcel sorting

Released Date: Mar 21, 2024 - 10:10 Article Source: Intelligent sorting

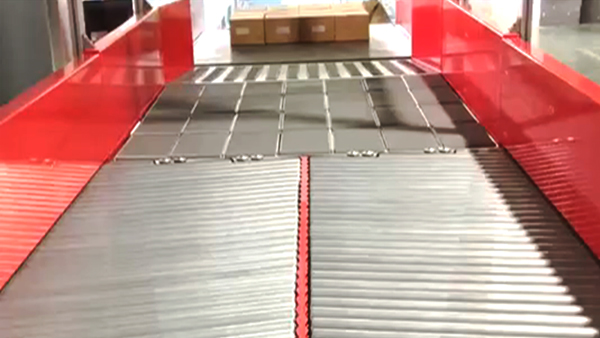

Linear Narrow-belt Sorter system

Logistics sorting efficiency determines competitiveness

Industry status quo

Industry status quo

Due to lack of funds and low degree of automation and intelligence, express terminal branches mainly rely on high density manual labor for on-site operation. 5% of the branches have a belt conveyor, and 75% use cage truck for sorting. Such operation mode affects the delivery time of express delivery and reduces service level.

Solution

Solution

Regional branches cooperate to jointly introduce intelligent sorting equipment, effectively improving sorting efficiency and making operations more time-saving and labor-saving. The higher the end efficiency, the higher the customer satisfaction.

Make policies as needed Rapid deployment

All types of packages achieve efficient and low-cost processing

Flexible layout

Flexible planning layout for sloping up or down section applications

Standard modular design

High standards of module standardization ensure fast and simple installation, and easy modification and expansion

Easy to control

Powerful, friendly, simple control system,Easy to operate

Core logistics equipment application

Focus on the innovation breakthrough of intelligent logistics equipment

Linear narrow-band sorter system

Swing arm sorter system

Visual separation of individual pieces

Dynamic automatic weighing, scanning